Glaoigh Linn

+86-19858305627

Ríomhphost Linn

sales@maple-machinery.com

Páirteanna cruach creimeadh-resistant le haghaidh oibríochtaí ola agus gáis Monaróirí

Soláthraíonn ár monarcha réitigh gaineamh, brionnú bás dúnta, brionnú bás oscailte, etc. Is iad dearadh foircneach, amhábhar ardchaighdeáin, ardfheidhmíocht agus praghas iomaíoch a theastaíonn ó gach custaiméir, agus sin an méid is féidir linn a thairiscint duit freisin. Glacann muid ardchaighdeán, praghas réasúnta agus seirbhís foirfe.

Táirgí te

Páirteanna Réitigh Iarainn Liath Mara

Chun ár spriocanna forbartha a bhaint amach, infheistíonn innealra Maple go leanúnach i bhforbairt ár ndaoine, ár bpróisis agus ár meaisíní. Cinntíonn infheistíocht agus nuálaíocht meaitseáil foirfe idir cheardaíocht iontach Páirteanna Réitigh Iarainn Liath Mara agus riachtanais shaol an lae inniu agus an lae amárach. Mar thoradh ar fhorbairt inmheánach leanúnach agus ar thóir na foirfeachta, aithnítear muid mar cheann de bhunaitheoirí an domhain mhóir. Is ceannaire soiléir muid sa teicneolaíocht a chuirtear i bhfeidhm i dteilgcheártaí agus i siopaí meaisíní, agus táimid an-bhródúil as an ngnóthachtáil seo.Innealra Talmhaíochta Páirteanna Gaibhnithe Cruach

Ar feadh níos mó ná 20 bliain, tá Maple Machinery Co., Ltd, atá lonnaithe i Ningbo, an tSín, ina mhonaróir gairmiúil gaibhneachta bás dúnta, ag speisialú i soláthar Páirteanna Gaibhnithe Cruach Innealra Talmhaíochta ardchaighdeáin do chustaiméirí. Ina theannta sin, is féidir linn seirbhísí breisluacha eile a sholáthar do tháirgí críochnaithe. Mar sin, más gá duit páirteanna brionnaithe agus meaisínithe, bíodh leisce ort teagmháil a dhéanamh linn!Páirteanna Réitigh Cruach Tionscal Trom

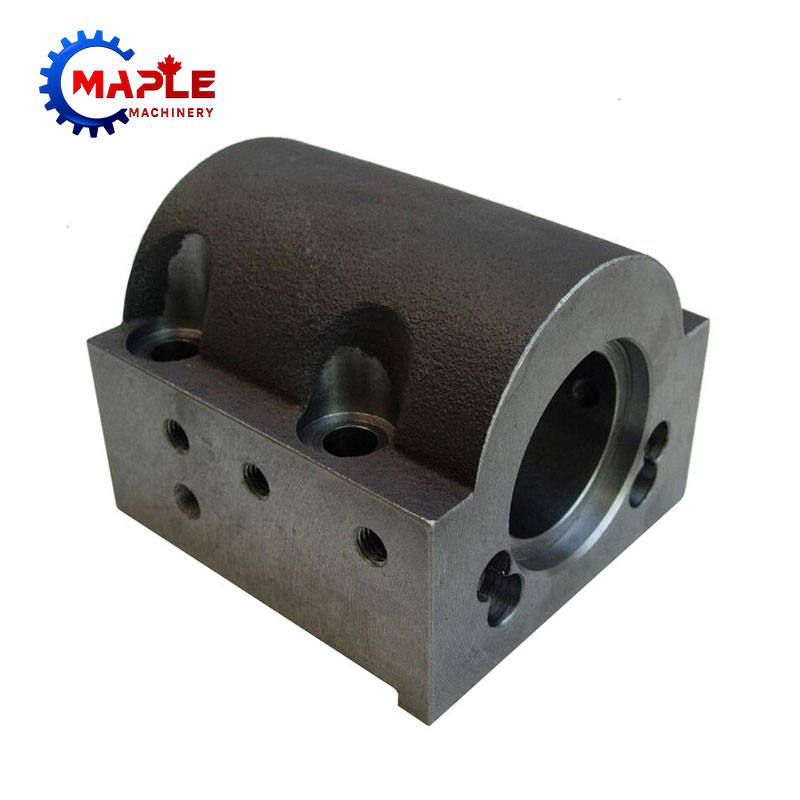

Tá níos mó ná cúig bliana déag de thaithí ag innealra Maple ag déantúsaíocht Páirteanna Réitigh Cruach Tionscal Trom. Déanfaimid seiceálacha ar an láthair ar gach próiseas agus déanfaimid iniúchadh idirmheánach 100%. Agus ní mór cumarsáid agus cumarsáid le custaiméirí a bheith tráthúil agus cruinn. Táirgí saincheaptha do chustaiméirí ní mór dúinn a bheith ar an chuid is mó professional.Among Maple innealra táirgí Réitigh, a chuirimid ar teilgin infheistíochta cruinneas le raon leathan de Tionscal Trom Páirteanna Réitigh Cruach. Úsáidtear ár teilgin infheistíochta cruach, cruach dhosmálta agus alúmanam go forleathan sa mhargadh crua-earraí. Is rogha iontach é an próiseas réitigh infheistíochta chun táirgí crua-earraí a tháirgeadh le toisí cruinn. Tá líon mór de na codanna méid beacht i Tionscal Trom.2. Paraiméadar Táirge (Sonraíocht)Innealtóireacht Shibhialta Páirteanna Gaibhnithe Cruach

Tá innealra Maple Co., TEO., atá lonnaithe i Ningbo, an tSín, ina mhonaróir Forging Parts le suíomh calafoirt den scoth agus seachadadh áisiúil, ag soláthar páirteanna brionnú Cruach Innealtóireachta Sibhialta ardchaighdeáin do chustaiméirí Innealtóireachta Sibhialta domhanda. Agus le torthaí maithe, is féidir linn seirbhísí breisluacha eile a sholáthar don táirge críochnaithe freisin.Off Highway Industry Steel Páirteanna Réitigh Céir Caillte

Maple machinery has a number of casting plants, with strong processing capacity Specializing in the production of carbon steel, alloy steel, stainless steel, high temperature alloy and other wax lost casting parts and machining parts. Maple's superior quality of Off Highway Industry Steel Lost Wax Casting Parts attracts equally excellent customers, enabling our products to serve various machinery industries. 产品内容 Off Highway Industry Steel Lost Wax Casting Parts Product Introduction Off Highway Industry Steel Lost Wax Casting Parts is a product that Maple machinery has been doing. Lost wax casting is now called investment casting. It is a precision casting process with little or no cutting. It is not only suitable for precision casting of various types and alloys, but also produces castings with higher dimensional accuracy and surface quality than other precision casting methods. In order to meet the needs of different customers, we use two kinds of wax, namely yellow low temperature wax and green medium temperature wax. 2. Product Parameter (Specification) Item Off Highway Industry Steel Lost Wax Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel/Casting Iron Certification ISO 9001:2015 Weight 0.01-5000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Sand Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Off Highway Industry Maple machinery has been increasing its manufacturing capacity for Off Highway Industry Steel Lost Wax Casting Parts for many years. Provide high quality Off Highway Industry Steel Lost Wax Casting Parts for our machining operations to meet and satisfy customer needs. We are able to process different types of castings, including: pressure die casting and sand castings. We assist our customers to select the most appropriate casting type according to the required volume and complexity, providing the most cost effective solution. The railway sector provides a crucial network for transport and distribution. It needs cost-effective and long-lasting equipment that is dependable for the range of applications. The railways, from freight to passenger, need different castings for various applications. Maple Machinery carries extensive experience to create steel castings and iron castings in varying sizes, shapes, and materials that are precise, strong, and durable. We manufacture a wide range of castings and forgings for railway infrastructure and transportation equipment. 4.Supporting Service for Off Highway Industry parts As mentioned above, in order to work in adverse conditions, the performance of the Off Highway Industry Steel Lost Wax Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Off Highway Industry parts We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Off Highway Industry Steel Lost Wax Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Off Highway Industry We have manufactured a wide range of Off Highway Industry Steel Lost Wax Casting Parts. The following are typical products: Coupling components, Centre plates, Bearing brackets, Rail wheels, Wheel hub, Base plate, Axle boxes, Yokes, Pedestals, Hinges, Tie plates, Side jaw clip, and Joint bar. 6. Why Sand Casting Sand casting is an ancient casting process where the metal parts are molded by pouring metal into a hollow cavity. The mold-based manufacturing process is used to make castings with materials of iron, steel, and Aluminum. Casting-based manufacturing includes several steps and can create a wide range of shapes and sizes for metal products. The process begins with the making of a mold pattern and a gate system with the exact size and shape of the required part. The temperature required depends on the metal as some metals take a long time to heat and melt. Maple Machinery has continuously upgraded its Sand-casting equipment and refined the casting process. The aim behind this is to use only the advanced casting technology for its Sand-casting operations. Each step follows the customer’s drawings and instructions to deliver precise solutions.Páirteanna Réitigh Gaineamh Iarainn Tionscal Ola & Gáis

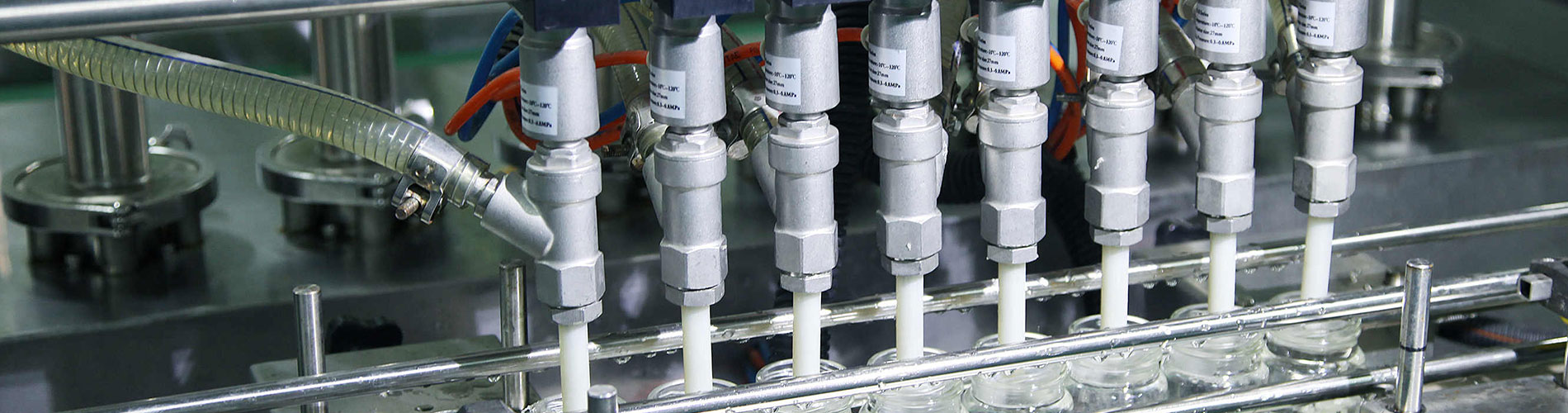

Tá na scileanna agus an taithí ag Maple Machinery chun Páirteanna Réitigh Gaineamh Iarainn Tionscal Ola & Gáis beachtas a sholáthar le haghaidh feidhmeanna ola agus gáis. Tá na páirteanna réitigh seo faoi réir coinníollacha oibre crua an t-am ar fad, mar sin ní mór na teilgin seo a bheith durable go leor chun oibriú ag teocht ard agus ard-neart. Trínár dteicneolaíocht réitigh chun cinn, is féidir linn páirteanna a tháirgeadh i gcruth glan nó in aice le cruth glan, ag soláthar friotaíocht creimeadh den scoth, neart agus friotaíocht caitheamh.

Seol Fiosrúchán

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy