Glaoigh Linn

+86-19858305627

Ríomhphost Linn

sales@maple-machinery.com

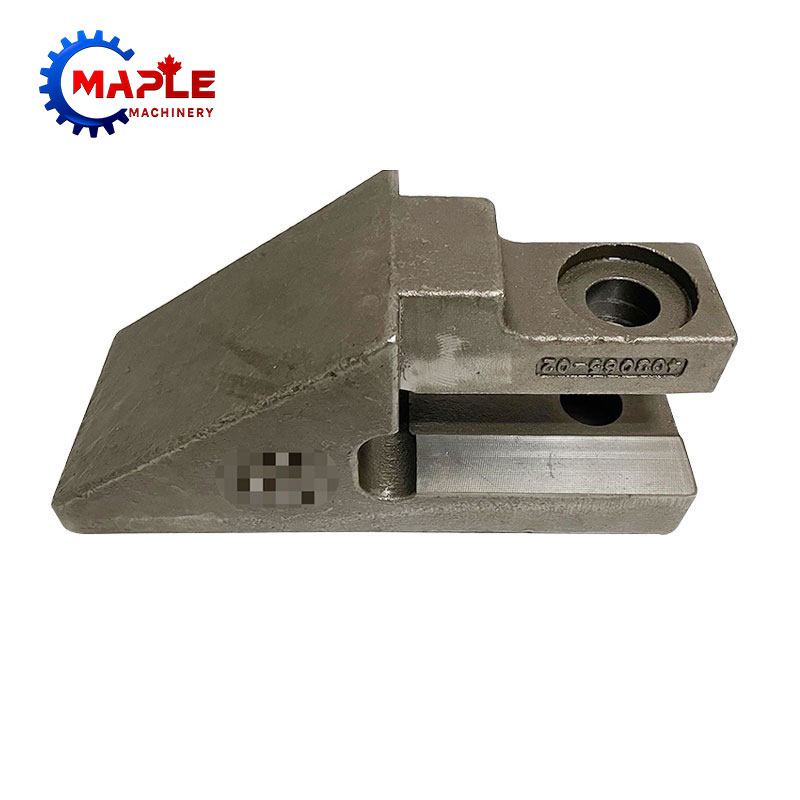

Comhlacht Comhla Réitigh Gaineamh Iarainn Insínte Monaróirí

Soláthraíonn ár monarcha réitigh gaineamh, brionnú bás dúnta, brionnú bás oscailte, etc. Is iad dearadh foircneach, amhábhar ardchaighdeáin, ardfheidhmíocht agus praghas iomaíoch a theastaíonn ó gach custaiméir, agus sin an méid is féidir linn a thairiscint duit freisin. Glacann muid ardchaighdeán, praghas réasúnta agus seirbhís foirfe.

Táirgí te

Páirteanna Réitigh Iarainn Liath Mara

Chun ár spriocanna forbartha a bhaint amach, infheistíonn innealra Maple go leanúnach i bhforbairt ár ndaoine, ár bpróisis agus ár meaisíní. Cinntíonn infheistíocht agus nuálaíocht meaitseáil foirfe idir cheardaíocht iontach Páirteanna Réitigh Iarainn Liath Mara agus riachtanais shaol an lae inniu agus an lae amárach. Mar thoradh ar fhorbairt inmheánach leanúnach agus ar thóir na foirfeachta, aithnítear muid mar cheann de bhunaitheoirí an domhain mhóir. Is ceannaire soiléir muid sa teicneolaíocht a chuirtear i bhfeidhm i dteilgcheártaí agus i siopaí meaisíní, agus táimid an-bhródúil as an ngnóthachtáil seo.Innealra Talmhaíochta Páirteanna Réitigh Gaineamh Cruach

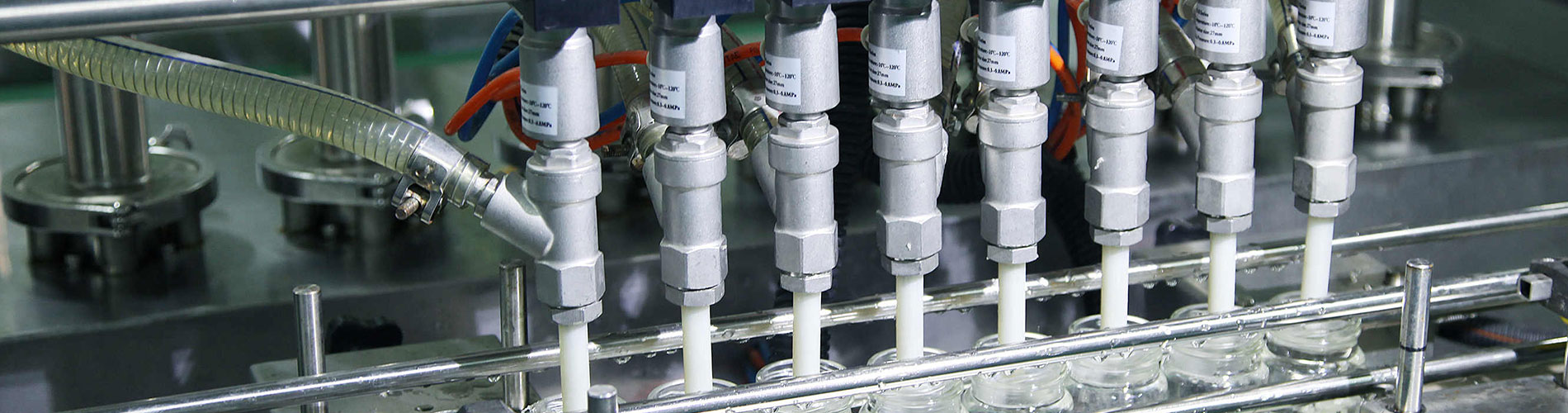

Is monaróir gairmiúil Innealra Talmhaíochta Páirteanna Réitigh Gaineamh Cruach é innealra Maple. Tá foirnéis againn a fhéadfaidh cruach dhosmálta, alúmanam, práis, iarann teilgthe agus cóimhiotail speisialta a leá. A bhuíochas lenár dteilgcheárta, tá an cumas againn go leor cineálacha páirteanna a mhonarú. I measc na samplaí tá comhpháirteanna uisciúcháin, impellers agus casings le haghaidh caidéil, agus caipíní faireoga agus feistis do chórais bleáin rothlacha agus scadán. Chomh maith lenár gcodanna féin a tháirgeadh, bainimid úsáid as ár dteilgcheárta freisin chun páirteanna beaga agus meánmhéide a olltáirgeadh a bhfuil gá acu le fiontair eile. Mar shampla, táimid ag monaróirí táirgí réitigh gaineamh le haghaidh páirteanna ardfheidhmíochta do thionscail na Mara agus na heitlíochta. Tá foirnéisí againn ar féidir leo gach cineál cóimhiotail a leá.Tionscal Athchúrsála Cruach Páirteanna Gaibhnithe Die Dúnta

Is cuma cén cruth atá ar do Chuid Páirteanna Die Gaibhnithe Cruach Dúnta Tionscal Athchúrsála, má tá gá le páirteanna miotail, is féidir Díolacháin Thionscail Réamhaisnéise a shaincheapadh duit ag innealra Maple. Níl anseo ach roinnt de na tionscail a ndéanaimid gaibhneachta agus teilgin speisialaithe a chruthú dóibh: aeraspáis Tógáil feithicleach & Déantúsaíocht trealaimh throma & Miotalóireacht Foraoiseacht Mianadóireacht Ola & Gás.Meaisín Próiseas Bia Páirteanna Réitigh Gaineamh Iarainn

Páirteanna teilgthe ardchaighdeáin, meaisínithe ar phraghsanna iomaíocha ó sholáthraithe iontaofa. Is monaróir cáiliúil páirteanna miotail é Maple Machinery sa tSín agus soláthraí iontaofa Meaisín Próiseas Bia. Éilíonn Meaisín Próiseas Bia Meaisín Próiseas Bia Ard-chruinneas Páirteanna Réitigh Gaineamh Iarainn. Tá muid in ann jab maith a dhéanamh de sholáthróirí táirgí móra na gcomhpháirteanna córais tábhachtacha go léir.Páirteanna Réitigh Gaineamh Iarainn As Tionscal Highway

Le beagnach dhá scór bliain, tá Maple Machinery ag soláthar teilgin iarainn theilgthe do thionscail éagsúla agus tá cáil air as teilgin ardchaighdeáin comhsheasmhacha a sheachadadh in am. Ag obair le gach cineál iarann liath agus insínte, soláthraíonn maple Páirteanna Réitigh Gaineamh Iarainn Off Highway Industry ardchaighdeáin agus seirbhís den scoth ar ghlanchostas íseal.Innealtóireacht Shibhialta Páirteanna Gaibhnithe Cruach

Tá innealra Maple Co., TEO., atá lonnaithe i Ningbo, an tSín, ina mhonaróir Forging Parts le suíomh calafoirt den scoth agus seachadadh áisiúil, ag soláthar páirteanna brionnú Cruach Innealtóireachta Sibhialta ardchaighdeáin do chustaiméirí Innealtóireachta Sibhialta domhanda. Agus le torthaí maithe, is féidir linn seirbhísí breisluacha eile a sholáthar don táirge críochnaithe freisin.

Seol Fiosrúchán

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy