Glaoigh Linn

+86-19858305627

Ríomhphost Linn

sales@maple-machinery.com

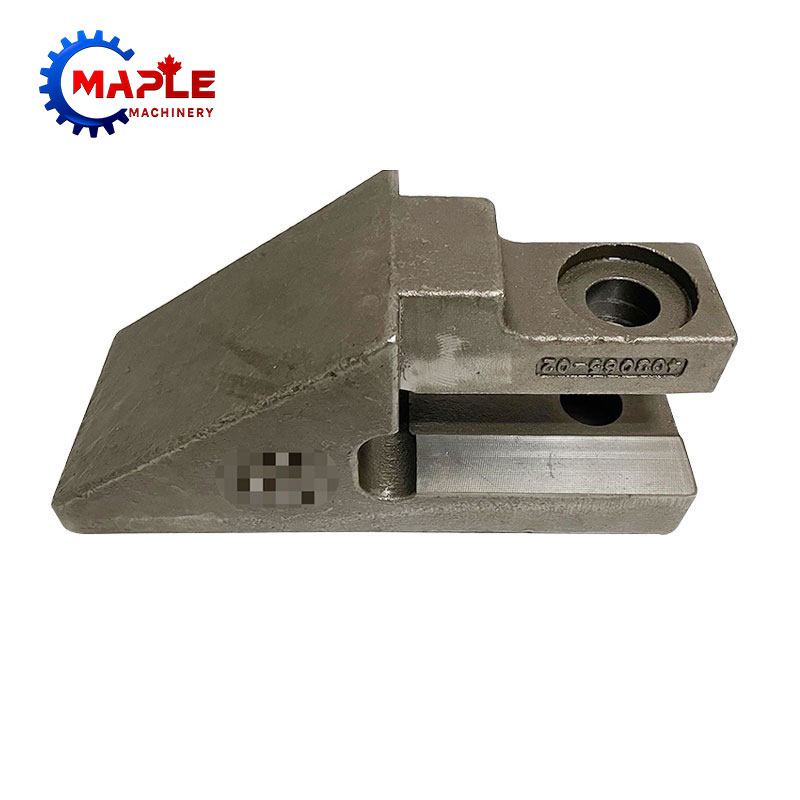

Múnlú gaineamh le haghaidh páirteanna comhla iarainn Monaróirí

Soláthraíonn ár monarcha réitigh gaineamh, brionnú bás dúnta, brionnú bás oscailte, etc. Is iad dearadh foircneach, amhábhar ardchaighdeáin, ardfheidhmíocht agus praghas iomaíoch a theastaíonn ó gach custaiméir, agus sin an méid is féidir linn a thairiscint duit freisin. Glacann muid ardchaighdeán, praghas réasúnta agus seirbhís foirfe.

Táirgí te

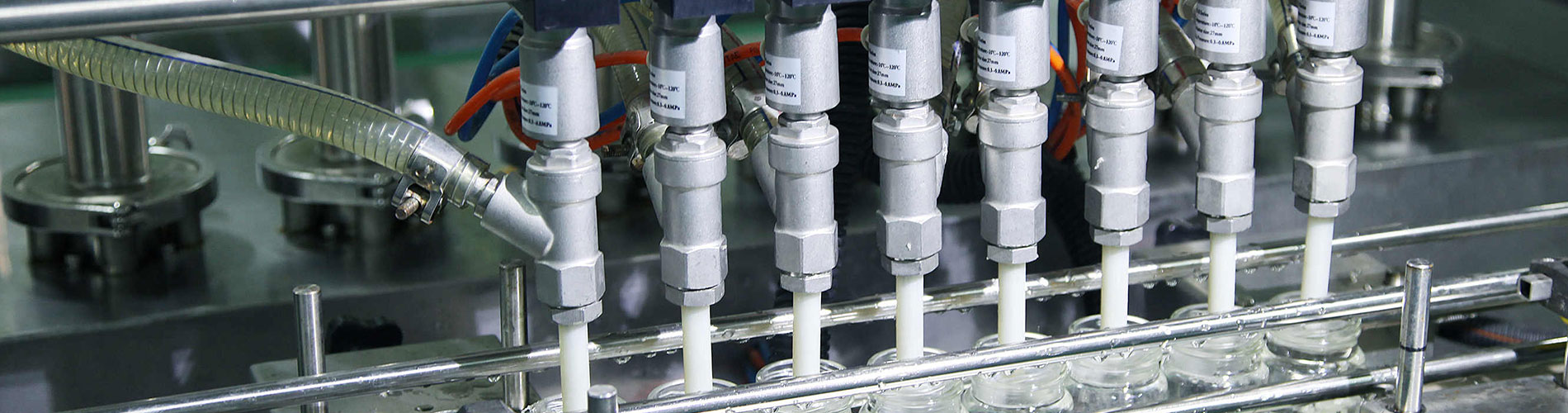

Tionscal Athchúrsála Páirteanna Réitigh Cruach Dhosmálta

Fostaíonn innealra Maple an teicneolaíocht is déanaí inár bpróiseas réitigh infheistíochta chun Páirteanna Réitigh Cruach Dhosmálta Tionscal Athchúrsála ardchaighdeáin a tháirgeadh go héifeachtach ó thaobh costais agus in am. Táimid i gcónaí ag lorg teicneolaíochtaí nua agus bealaí nuálacha chun ár bpróiseas réitigh infheistíochta Tionscal Athchúrsála a fheabhsú, ár n-éifeachtúlacht, ár gcáilíocht, agus ár n-am luaidhe a ghiorrú.Innealra Tógála Páirteanna Réitigh Cruach

Ag innealra Maple, is é cáilíocht, sábháilteacht agus seirbhís ár bpríomh-iomaíochas. Tá trealamh meicniúil chun cinn agus solúbthacht ag ár teilgcheárta, ar féidir leo freastal ar do chuid riachtanas Páirteanna Réitigh Cruach Innealra Tógála agus cabhrú leat freastal ar riachtanais éilitheacha custaiméirí. Tá ár dteilgcheárta tiomanta do shábháilteacht, glaineacht agus éifeachtúlacht a chothabháil. Thar na blianta, tá Maple ag infheistiú go leanúnach sa trealamh is airde chun cinn, rud a fhágann go bhfuil sé ar thús cadhnaíochta sa tionscal.Páirteanna Gaibhnithe Cruach Dhosmálta Tionscal Ola & Gáis

Tá innealra Maple lonnaithe i Ningbo, an tSín le haghaidh a tháirgeadh Páirteanna, trádstóráil agus fo-iompar de na Páirteanna Gaibhnithe Cruach Dhosmálta Tionscal Ola & Gáis, agus tá sé suite go maith chun freastal ar riachtanais na soláthróirí móra sa tionscal ola agus gáis. In éineacht le soláthraithe deimhnithe agus ceadaithe ónár gcustaiméirí i dtíortha iomadúla, tá an deis agat leas a bhaint as na buntáistí a bhaineann le foinsiú tíre ar chostas íseal agus tá a fhios agat go bhfuil ráthaíocht cáilíochta 100% ann a bhuíochas le táirgí Maple.Tionscal Athchúrsála Páirteanna Réitigh Beachtais Cruach

Chuir innealra Maple seirbhís shaincheaptha den chaighdeán is airde ar fáil i gcónaí maidir le Páirteanna Réitigh Cruach Beachtais Tionscal Athchúrsála. Cuirimid an leibhéal is airde páirteanna agus seirbhísí ardchaighdeáin ar fáil dár gcustaiméirí. Tá ár seirbhís Páirteanna Réitigh Beachtais Cruach Tionscal Athchúrsála deartha chun freastal ar riachtanais chruinne ár gcustaiméirí agus tá ár bhfoireann tiomanta do luach a sholáthar trí innealtóireacht bheachtais agus cumas nuálaíoch uirlisí.Tionscal Athchúrsála Páirteanna Réitigh Cruach

Is soláthraí cruach teilgthe é innealra Maple. Úsáidtear an modh "céir caillte" chun teilgin casta a tháirgeadh le cruinneas an-ard. Mar thoradh ar an gcur chuige ginearálta seo, tá domhanleithead suntasach ag ár n-innealtóirí i ndearadh táirgí, Páirteanna Réitigh Cruach an Tionscail Athchúrsála agus roghnú ábhar. Ciallaíonn sé seo gur féidir linn, i gcomhairle leat, na teilgin is fearr a tháirgeadh don Tionscal Athchúrsála a chomhlíonann do mhianta agus riachtanais chruinne. Is é innealra Maple do chomhpháirtí forbartha le haghaidh réitigh rathúil, leis an sprioc an réitigh is fearr a bhaint amach trí chomhairliúchán frithpháirteach.Páirteanna Réitigh Gaineamh Iarainn Mara

Tá innealra Maple tiomanta dá chumais Páirteanna Réitigh Gaineamh Iarainn a fheabhsú agus tá muinín ár gcustaiméirí tuillte aige trí infheistíocht a dhéanamh inár dtrealamh chun cruinneas ár dtáirgí a fheabhsú. Soláthraímid seirbhís ardchaighdeáin agus leibhéal réitigh den scoth dár gcustaiméirí i bPáirteanna Réitigh Gaineamh Iarainn Mara. Is é an rud is fearr is féidir linn a fháil ná muinín leanúnach ár gcustaiméirí.

Seol Fiosrúchán

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy