Glaoigh Linn

+86-19858305627

Ríomhphost Linn

sales@maple-machinery.com

Teilgin iarainn insínte Monaróirí

Soláthraíonn ár monarcha réitigh gaineamh, brionnú bás dúnta, brionnú bás oscailte, etc. Is iad dearadh foircneach, amhábhar ardchaighdeáin, ardfheidhmíocht agus praghas iomaíoch a theastaíonn ó gach custaiméir, agus sin an méid is féidir linn a thairiscint duit freisin. Glacann muid ardchaighdeán, praghas réasúnta agus seirbhís foirfe.

Táirgí te

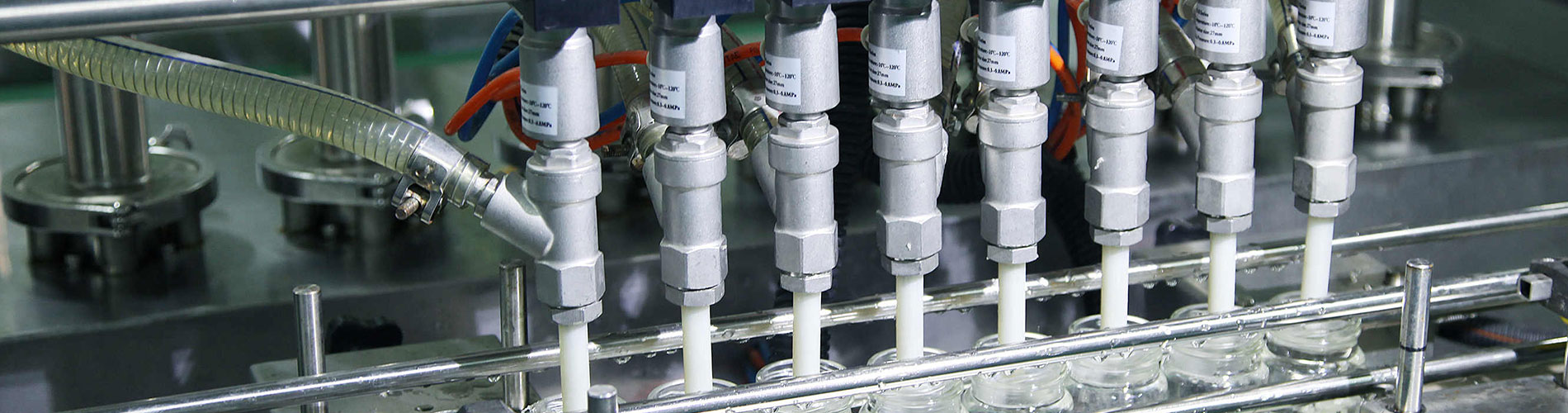

Innealra Talmhaíochta Páirteanna Réitigh Cruach Dhosmálta

We have rich experience in the field of steel, steel, aluminum, special alloy and other agricultural machinery. All Agricultural Machinery Stainless Steel Casting Parts are made by different processes, including sand casting, investment casting, centrifugal casting, die casting, forging, machining, etc. We have been serving international industrial markets for more than 15 years. Our primary goal is to retain the loyalty of existing customers and win new business through exemplary customer service, low cost, high quality, fast shipping, complete order fulfillment and custom processing. 产品内容 Agricultural Machinery Stainless Steel Casting Parts Product Introduction Maple machinery's services include heat treatment, machining and surface treatment. Heat treatment involves heating and cooling a metal to change the physical and mechanical properties of Agricultural Machinery Stainless Steel Casting Parts. Heat treatment controls properties such as hardness, strength, toughness, ductility, and elasticity. We also offer a full range of machining services. With our surface treatment service, we can treat your products to improve corrosion resistance, wear resistance and appearance. 2. Product Parameter (Specification) Item Agricultural Machinery Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Agricultural Machinery Maple machinery is one of the trusted and reliable manufacturers and suppliers of Stainless Steel Casting Parts, Vick serves the global needs of Agricultural Machinery Stainless Steel Casting Parts and ensures high quality products and on-time delivery in every transaction. In our foundry, we mainly process carbon steel and alloy steel materials. We inherited the casting process from our great-grandfather, and have a skilled labor force and professional technical experts to meet different needs. 4.Supporting Service for Agricultural Machinery As mentioned above, in order to work in adverse conditions, the performance of the Agricultural Machinery Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Agricultural Machinery Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Agricultural Machinery We have manufactured a wide range of Agricultural Machinery Stainless Steel Casting Parts. The following are typical products: Brackets, Rototiller tines, Tillage Points, Seed Drills, Chain Sprocket Locust Harrows, Levers, Plough, Pivots, Covers, Clevises, Handles and Latches, Suitcase Weights, Pumps & Valves, and Hardware.. 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.Réitigh Iarainn Insínte

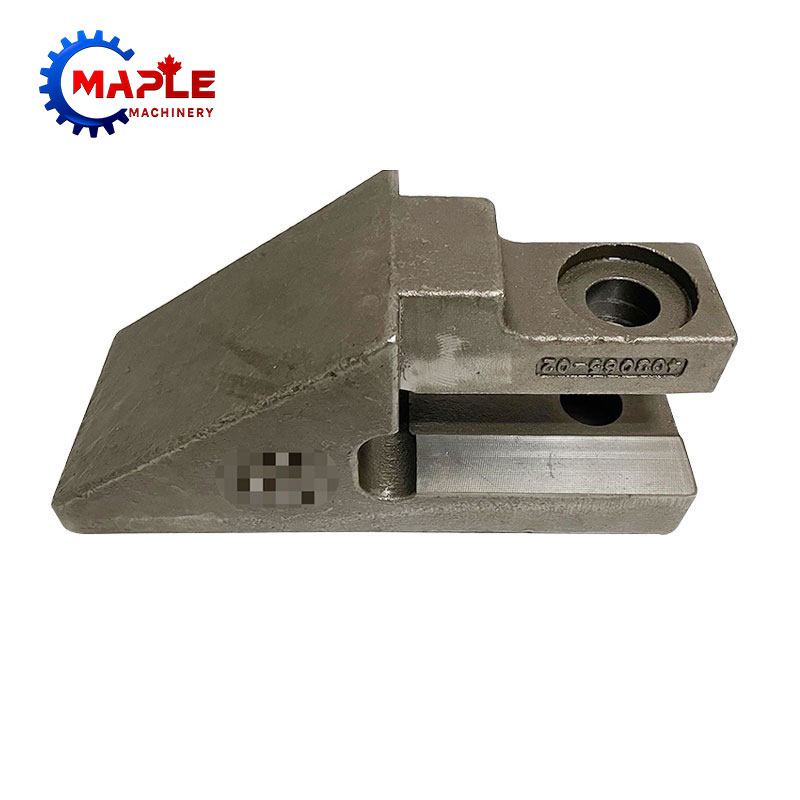

Déantar ár dTeilgin Iarainn Insínte a dhearadh go cúramach ag baint úsáide as ardteicnící teilgcheárta chun feidhmíocht eisceachtúil a sheachadadh i raon leathan feidhmchlár. Ar a dtugtar as a neart teanntachta ard, marthanacht agus insínteacht, cuireann na teilgin seo friotaíocht níos fearr ar chaitheamh, ar thionchar agus ar strus teirmeach. Le comhdhéanamh miotalóireacht beacht agus ceardaíocht shaineolach, déantar ár dteilgin iarainn insínte a innealtóireacht chun na caighdeáin tionscail is airde a chomhlíonadh.Páirteanna Gaibhnithe Cruach Dhosmálta Lasmuigh den Tionscal Highway

Cuireann innealra Maple raon leathan Páirteanna Gaibhnithe Cruach Dhosmálta Off Highway Industry ar fáil do chustaiméirí. Is é ár n-inniúlacht lárnach ná réitigh chórais shainiúla do chustaiméirí a fhorbairt don Tionscal Off Highway chun freastal ar na riachtanais is déine. Chomh maith le toirt, cruinneas, sábháilteacht agus iontaofacht, tá ár gcustaiméirí ag iarraidh níos mó teicneolaíocht níos fearr agus éifeachtúlacht eacnamaíoch.Tionscal Trom Páirteanna Réitigh Gaineamh Cruach

Déanann innealra Maple speisialtóireacht i bPáirteanna Réitigh Gaineamh Cruach Tionscal Trom ardchaighdeáin agus soláthraíonn sé orduithe táirgeachta toirte ardchaighdeáin agus táirgeadh aon mhíre. Is é an t-ábhar is mó de na teilgcheárta gráid éagsúla steel.High chaighdeán réitigh réitigh múnlaí a cheadú le haghaidh próiseála ina dhiaidh sin le corrlach íosta. Soláthraíonn cruach teilgthe táirgí le céimseata casta agus mar sin is minic gurb é an t-aon bhealach chun táirgí miotail a bhfuil struchtúr casta acu a tháirgeadh.Innealra Tógála Páirteanna Réitigh Cruach

Ag innealra Maple, is é cáilíocht, sábháilteacht agus seirbhís ár bpríomh-iomaíochas. Tá trealamh meicniúil chun cinn agus solúbthacht ag ár teilgcheárta, ar féidir leo freastal ar do chuid riachtanas Páirteanna Réitigh Cruach Innealra Tógála agus cabhrú leat freastal ar riachtanais éilitheacha custaiméirí. Tá ár dteilgcheárta tiomanta do shábháilteacht, glaineacht agus éifeachtúlacht a chothabháil. Thar na blianta, tá Maple ag infheistiú go leanúnach sa trealamh is airde chun cinn, rud a fhágann go bhfuil sé ar thús cadhnaíochta sa tionscal.Innealtóireacht Shibhialta Páirteanna Réitigh Beachtais Cruach

Tá innealra Maple ag monaróir Páirteanna Réitigh Beachtais Cruach le haghaidh éagsúlacht riachtanas tionsclaíoch. Táimid bródúil as luach a chur le do Pháirteanna Réitigh Beachtais Cruach. Tá Páirteanna Réitigh Beachtais Cruach Innealtóireachta Sibhialta ar cheann dár go leor táirgí, Tá taithí againn i ndéantúsaíocht Páirteanna Réitigh Beachtais Cruach Innealtóireachta Sibhialta. Tagann muinín as ár níos mó ná 15 bliain de thaithí déantúsaíochta.

Cuardach Gaolmhar

Seol Fiosrúchán

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy